Aluminum alloy is a common lightweight metal material, widely used in automobiles, ships, electronics, aerospace and other fields. With the need for weight reduction, the demand for aluminum alloy parts continues to increase. Among all the forming processes of aluminum alloy parts, die casting is a casting method with the fastest production speed and higher quality of formed parts. It is a method of quickly filling a metal mold cavity with liquid aluminum alloy or semi-liquid aluminum alloy under high pressure, and rapidly solidifying under high pressure to obtain castings.

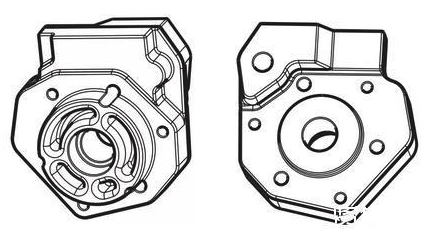

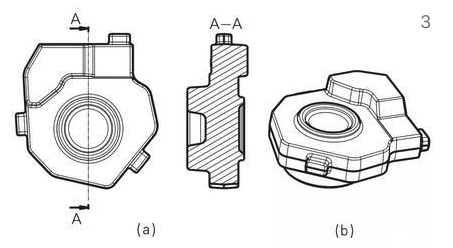

An aluminum alloy splitter for high-pressure oil pumps for automobiles (as shown in Figure 1). Due to its complicated shape and thick thickness, the part where the liquid metal contacts the mold surface during the die-casting process cools faster than the inside of the liquid metal. After solidification is complete Shrinkage cavities or shrinkage defects are easily formed in the casting. In addition, due to the high degree of overheating of molten metal during pouring, there are serious entrainment and oxidation phenomena during the filling process, resulting in more pores and inclusions in the casting. The existence of these shrinkage pores, pores and inclusions causes a high scrap rate of aluminum alloy shunts, serious waste of materials and energy, and huge risks to the performance of the product.

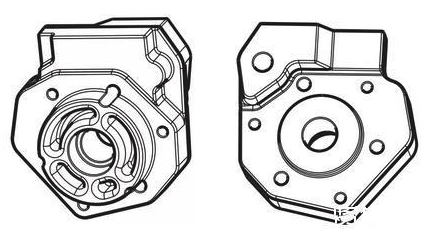

Compared with the casting process, the forging process can effectively avoid the occurrence of such defects. However, due to the different characteristics of the forging process and the casting process, the shape of the part must be modified accordingly. Only by designing a forging drawing that meets the requirements of the forging forming process, a reasonable forging die structure and selecting the correct die forging steps can forging and producing products with better quality and higher yield.

Analysis of the forging process of aluminum alloy splitter

Forging drawing design

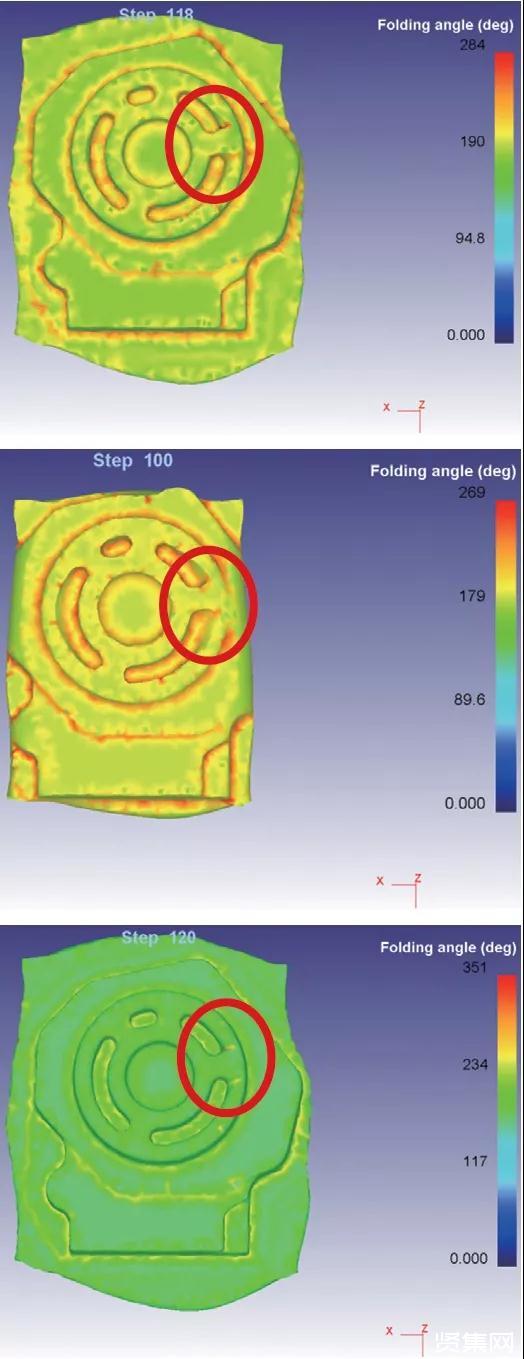

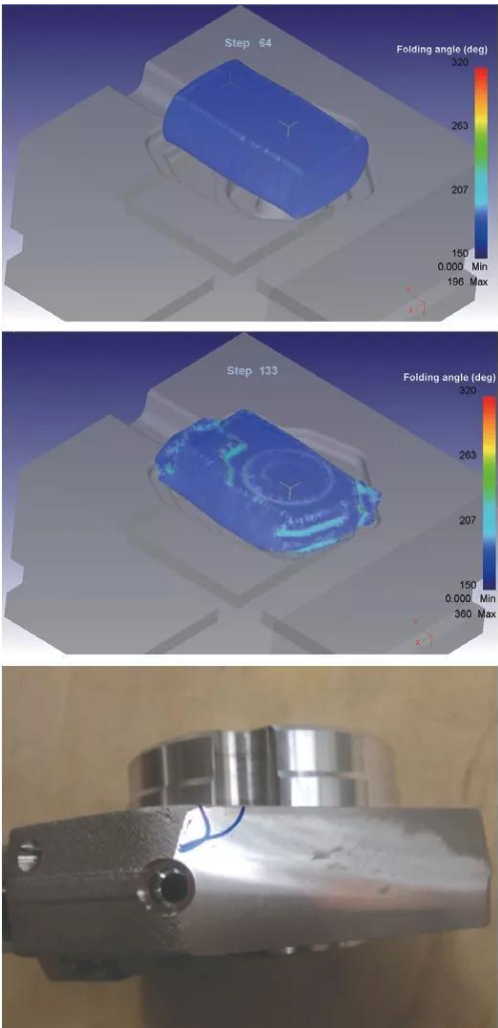

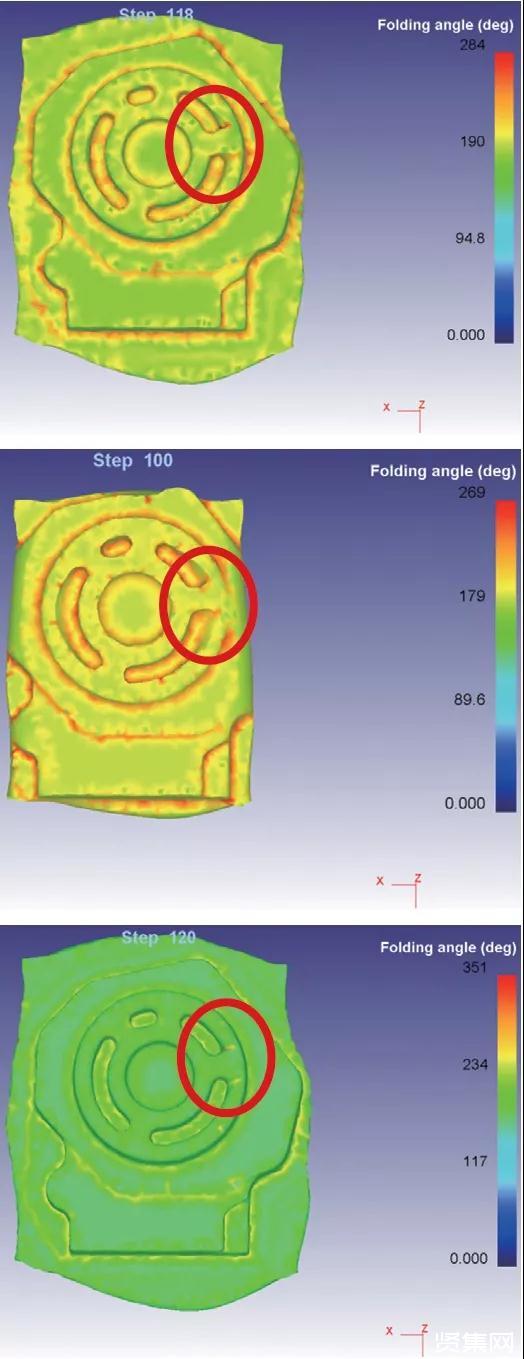

Taking the structural shape and size of the casting drawing as a reference, 6 through holes with a smaller diameter and 1 blind hole must be filled in the aluminum alloy shunt forgings, and the through hole with a larger middle diameter is designed as a blind hole. According to the finite element numerical simulation analysis of the forging process, if the four waist-shaped blind holes on the large cylinder are retained, creases are likely to appear during the forging process, as shown in Figure 2, so the customer is required to modify the structure of this part.

At the same time, all the mold exit angles on the original casting drawing are 1°. Because aluminum alloy is easy to stick to the mold during the forging process, the forging mold inclination is usually designed to be 5°~7°, but the larger the mold exit inclination will be Increase material consumption. After communicating with the customer, the outer draft angle of the forging is designed to be 3°, and the inner draft angle is designed to be 5°.

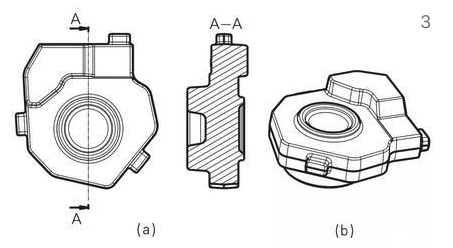

In addition, the machining unit proposed to add three machining process briquettes to the forgings according to the product processing requirements, with a thickness of 10-15mm and a briquette width of about 10mm. Considering these requirements, the final design of the forging is shown in Figure 3.

Technical requirements for forgings

⑴Material.

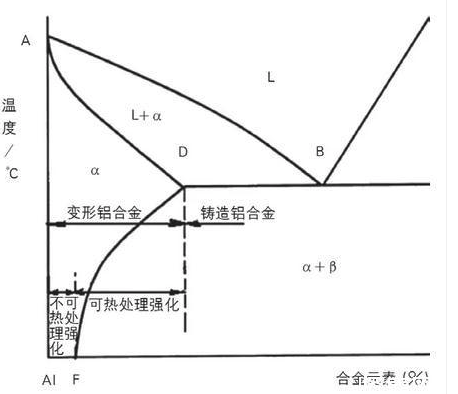

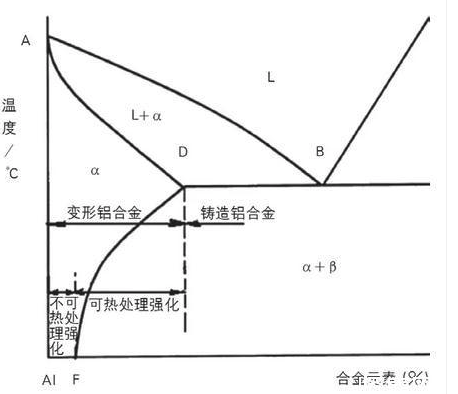

Aluminum alloy is formed by adding various elements such as manganese, magnesium, copper, silicon, iron, nickel, and zinc to aluminum as the matrix. According to the difference in composition and process performance, aluminum alloys are divided into two categories: wrought aluminum alloys and cast aluminum alloys, as shown in Figure 4.

In the original die-casting process, the material used is A380 cast aluminum alloy, which belongs to the Al-Si-Cu series alloy. It has high silicon content, is easy to mold, easy to machine, and has good heat conduction. The product's tensile strength requirement is 320MPa, the yield strength is 160MPa, and the elongation is 3.5%. The forged aluminum materials corresponding to this strength include 6 series Al-Mg-Si series materials, of which the strength of 6061 is about 330MPa. Excellent performance, good corrosion resistance, high toughness, no deformation after processing, compact material without defects, etc. Therefore, we choose 6061 as forged aluminum.

⑵ Heat treatment requirements.

The T6 heat treatment process is required, that is, solid solution + aging treatment. Among them, solution treatment: 530±5°C (4h), quenching (water temperature 60±10°C), aging treatment: 175±3°C (heat preservation 8h)

Organization and performance requirements:

1) Hardness ≥80HB (about 47HRB).

2) Mechanical properties (yield strength ≥241MPa, tensile strength ≥262MPa, A≥7%)

3) Metallographic structure: no overburn.

⑶ Other technical requirements.

1) Cracks, inclusions, etc. are not allowed on the surface of the forging, and the surface must be smooth. Knock bruises shall not exceed 2.5mm×1.5mm×1.0mm.

2) The cutting edge burr is not more than 0.3mm.

3) The draft angle of the outer circle is 3°, and the draft angle of the inner circle is 5°.

4) The upper tolerance of the forging thickness is +1.2mm, the lower tolerance is -0.6mm, and the tolerance of other dimensions is ±0.5mm.

Forging process analysis

Aiming at the degree of shape, dimensional accuracy, material and quality requirements of aluminum alloy shunt forgings, the forging method and process are preliminarily determined as follows:

Material inspection → blanking → heating → forging → trimming → T6 treatment → inspection → shot peening → final inspection → warehousing.

⑴ Material inspection.

For the incoming aluminum alloy raw materials, in addition to checking the chemical composition according to the standard, it is also necessary to focus on the internal quality.

Aluminum alloy raw materials for die forging generally use ingots or extruded billets. Ingot billets often have defects such as looseness, pores, shrinkage, slag inclusion, dendritic segregation and other defects. The extruded billet is heated to the ingot, then placed in a preheated mold, and extruded into shape. Through hot extrusion deformation, the as-cast structure of aluminum alloy can be greatly improved, the grains are refined, and the performance is greatly improved. However, there may also be coarse crystal rings, layering, shrinking tails, slag inclusion, oxide film and skin. Defects such as bubbles. The above-mentioned defects of aluminum alloy raw materials may cause cracks during forging and directly affect product quality.

For some key auto parts, such as aluminum alloy raw materials for control arms, strict control of the coarse-grain ring is usually required.

⑵Unloading.

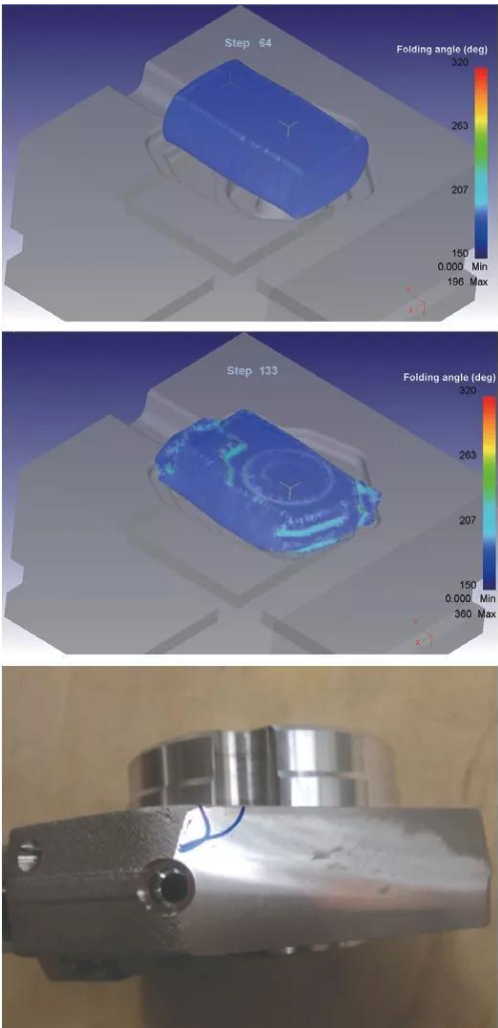

The diameter and length of the blank should be as close as possible to the size and shape of the forging, and the blanking end surface should be flat and able to cover the cavity of the forging die to eliminate the convolution of the blank end surface during the forming process and prevent the formation of wrinkles on the surface of the forging. The problem (as shown in Figure 5).

For aluminum alloy, sawing and lathe blanking are commonly used blanking methods.

⑶ Heating.

The initial forging temperature of 6061 aluminum alloy is 482℃, the final forging temperature is 432℃, and the temperature range is only 50℃. Because the aluminum alloy forging temperature range is very narrow, and the color of the aluminum alloy does not change when heated to about 400°C, the temperature cannot be judged with the naked eye. Therefore, the heating furnace must maintain a precise temperature. Aluminum alloy blanks are most suitable for heating in resistance furnaces with forced air circulation and automatic temperature adjustment. In order to avoid uneven heating, the blank should be placed 250~300mm away from the furnace door when placed in the furnace.

Due to the complex phase composition of aluminum alloy, in order to ensure that the strengthening phase is fully dissolved, the heating and holding time is longer than that of ordinary carbon steel, and the higher the degree of alloying, the longer the holding time. The heating and holding time is reasonable, and the aluminum alloy has good plasticity, which can improve the forging performance of the aluminum alloy.

The holding time of most aluminum alloy blanks is calculated according to the diameter or thickness of the blank 1.5-2min/mm (multiplied by the diameter or thickness of the blank to obtain the required holding time), and the heating and holding time of high-strength aluminum alloys should be calculated at 2-3min/mm. The upper limit of the alloy element content is higher, and the upper limit is taken for the larger diameter or thickness, and the time for repeated heating can be halved. Whether the extruded and rolled billets need to be kept warm after they are heated to the forging temperature, subject to no cracks during forging, while for aluminum ingots, they must be kept warm

The first batch of 300 shunt samples submitted by our company were directly forged after medium-frequency electric induction heating, and an internal crack was found in machining (Figure 6). The Dongfeng Technology Research Institute analyzed that it was related to the heating quality. Therefore, it was decided to purchase a resistance furnace heating with forced air circulation and automatic temperature adjustment. Similar quality problems have never occurred.

⑷Forging.

Aluminum alloy forging has the following characteristics:

1) Aluminum alloy has a high coefficient of friction and strong adhesion during forging, so the fluidity of aluminum alloy is poorer than that of other alloys. A good lubricant must be used during forging. The quality of lubrication will affect the forging force. , Forging defects, grain flow lines, etc. The lubricants commonly used for aluminum alloy forging are oil-based lubricants made of high-purity particulate graphite.

2) The critical degree of deformation of aluminum alloy is 12% to 15%, and the degree of deformation at the final forging temperature should be controlled to be less than 12% or greater than 15%. Otherwise, aluminum alloy forgings are prone to large grains; in addition, rough surface of the mold, uneven deformation, low final forging temperature, high quenching temperature, and long time will all cause large coarse grains. Generally speaking, for aluminum alloy forgings produced by hydraulic presses, the surface roughness of the die is required to be Ra0.4μm. For hot die forging presses, due to the relatively fast forging speed and the effect of oily lubricants, the surface roughness of the forging die is within Ra1.6μm is sufficient.

3) Due to the good thermal conductivity of aluminum alloy, the forging temperature range is very narrow. If the mold is not preheated or the preheating temperature is not enough, cracks will also occur. Therefore, the forging tools and forging dies should be fully preheated. To this end, we have developed a method of using natural gas online baking molds to ensure that the mold temperature is always around 430°C, which is basically the same as the blank temperature, to achieve isothermal forging of aluminum alloy. Practice has proved that the use of isothermal forging process, aluminum alloy has good fluidity and filling properties, small deformation resistance, avoids the external surface and internal defects of the forging, and the quality meets the technical requirements of similar foreign forgings.

⑸Cut the edges.

The die forging process of aluminum alloy forgings is basically the same as that of steel forgings, followed by billet making, pre-forging, and final forging. Cold trimming is usually used after forging. There is a big difference between the trimming process of aluminum alloy forgings and that of steel forgings, which is mainly reflected in the difference between the edge of the trimming die and the body of the forging when the aluminum alloy is cooled and trimmed after forging. The gap should be 1.2 to 1.5 times larger than that of steel forgings, otherwise it is easy to tear off a layer of bark (similar to bark) from the surface of the forging while cutting off the flash, as shown in Figure 7. On the one hand, it may be related to the softer aluminum alloy material after forging, and on the other hand, it may be related to the critical deformation degree near the flash edge of the aluminum alloy forging, resulting in the formation of a coarse-grained structure near the flash edge. Of course, the small outside draft angle (2°~3°) of the forging may also have a certain influence.

Isothermal forging process, precautions and preventive measures of aluminum alloy splitter

Figure 7 Cutting edge gnawing injury

To solve this problem, the current solution is to trim the edge in two times. The first trimming is performed after forging to cool to room temperature. The gap between the cutting edge and the forging body is large, so that the cutting edge is farther away from the forging body. After trimming, the remaining burrs on the forgings are relatively large, then the aluminum alloy forgings are treated with T6 heat treatment to increase the hardness of the forgings, and then trimming is performed a second time to remove the remaining burrs on the forgings. Figure 8 shows the effect of fine trimming.

Isothermal forging process, precautions and preventive measures of aluminum alloy splitter

Figure 8 The quality of fine trimming

Forging die design

The most important thing in forging die design is the design of the pre-forging die and the setting of the parting surface, and it must be considered that the forging streamline is shaped in accordance with the direction of the product load stress.

Billet step

Through simulation analysis, the blank specification of the aluminum alloy shunt is φ83mm×137mm. Considering the versatility of the material specification, the blanking specification is selected as φ80mm×150mm, and then it is upset to a height of 137mm and a diameter through a blanking process. φ83mm. During the process debugging, it was found that the tensile stress on the outer surface of the upsetting billet in this way would increase the risk of cracking on the billet surface, especially when the billet heating temperature is close to the over-sintering temperature, the billet will explode as soon as it is upset, and the exploded texture The texture is similar to that of a tree pole, as shown in Figure 9.

Isothermal forging process, precautions and preventive measures of aluminum alloy splitter

Figure 9 The burnt parts are upset and open

In order to avoid risks, through the improvement of the pre-forging die structure, the blank making process is improved to directly lie flat and flatten the blank to a thickness of 50mm, and then place it on the pre-forging die for forming.

Pre-forging step

Some experts believe that for aluminum alloy forging, a semi-closed structure must be used to make the aluminum alloy form under three-way pressure. In order to verify the correctness of this point of view, we first designed the pre-final forging dies according to the open die forging structure. After production verification, both the pre-forging and final forging are designed according to the open die forging process plan, and qualified forgings can be formed completely, but the material utilization rate is slightly lower.

Subsequently, the pre-forging die is improved to an extrusion barrel structure, and the lower die adopts two ejector rods one after the other to ensure stable ejection. Since the ejecting action of the equipment used is more reliable, in order to ensure that the forgings stay in the lower die as much as possible, the lower die ejector rod ejects the cavity, and the lower die jaw shape is designed into a bell mouth shape with a small front and a large back. The shape of the flash increases the resistance of the forging that is not brought up by the upper die.

For the final forging step, the open forging structure is still used. The ejection method is the same as that of the pre-forging die. The upper die adds an ejector pin, and the lower die is changed to two ejector pins, one in front and one in the back. Shaped ejector rod, so that the two ejector rods are pushed up at the same time, to ensure that the forging is smoothly separated from the lower die.

Determination of equipment tonnage

The tonnage of forging equipment is related to the forging method, product shape, deformation resistance of the material and other factors. The average forging pressure of ordinary forgings is 3.0 tons/cm², and the forging force can be calculated by multiplying this value by the projected area relative to the forging direction. The thinner the web thickness and flash thickness, the higher the forging pressure, and the web thickness is proportional to the projected area of the forging.

in conclusion

⑴Different from the production process flow of steel molds, the process flow of aluminum alloy forgings is: material inspection → sawing and cutting → heating → forging → rough trimming → T6 treatment → hardness inspection → fine trimming → shot peening → final inspection →Warehousing→Delivery.

⑵Using the method of natural gas online baking mold, to ensure that the mold temperature is always around 430℃, and realize the isothermal forging of aluminum alloy.

⑶Using rough and fine trimming process twice. When rough cutting, the flash is pressed tightly with a compression ring, the gap between the edge trimming die and the forging is controlled to be above 0.6mm, and the remaining burrs on the forging are larger; then T6 heat treatment is performed to increase the hardness and refine the grain; finally, the fine Trim the edges and remove the remaining burrs to ensure that the quality meets the requirements of the drawings.