DIN 1.0909 Ti Alloy

Our advantages

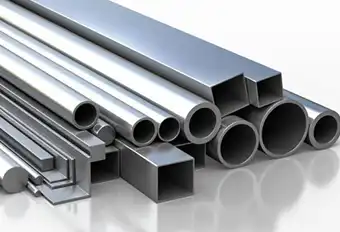

DIN 1.0909 properties and heat treatment forged piece, Including DIN 1.0909 application and specifications, We have all specifications,Including DIN 1.0909 steel plate, DIN 1.0909 sheet, DIN 1.0909 square steel, DIN 1.0909 flat bar,DIN 1.0909 round bar,DIN 1.0909 forgings, we can own production and sales.

Introduction to Our Products:

Specialized high quality steel

We have the advantages of equipment, technologies and price

forged/hot rolling/ extrusion of steel

We can produce the DIN 1.0909 has the following specifications:

Round bar steel: 1mm to 3000mm

Square-shape steel: 1mm to 2000mm

Plate steel:0.1mm to 2500mm

Width: 10mm to 2500mm

Lenth: We can supply any lenth based on the customer's requirement.

Forging: Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes

Tubings: OD: φ6-219 mm, with wall thickness ranging from 1-35 mm.

Finished goods condition: hot forging/hot rolling + annealing/normalizing + tempering/quenching + tempering/any conditions based on the customer's requirement

Surface conditions: scaled (hot working finish)/ground/rough machining/fine machining/based on the customer's requirement

Furnaces for metallurgical processing: electrode arc + LF/VD/VOD/ESR/Vacuum consumable electrode.

Ultrasonic inspection: 100% ultrasonic inspection for any inperfections or based on the customer's requirementExcellent service for all kinds of industries,with advantages of technologies, equipment and price.

We serve you with our honesty, integrity, and professionality.

Chemical composition % of the ladle analysis of grade DIN 1.0909 and Standards

| Category | steel |

| Class | Alloy steel |

| Type | Standard |

| Common Names | Silicon-manganese steel |

| Designations |

France: AFNOR 60 S 7 , AFNOR 61 SC 7 Germany: DIN 1.0909 United Kingdom: B.S. 250 A 58 United States: ASTM A29 , ASTM A322 , ASTM A331 , ASTM A505 , ASTM A519 , ASTM A59 , SAE J1268 , SAE J404 , SAE J412 , SAE J770 , UNS G92600 |

| Composition |

|

| Mechanical Properties |

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Density (×1000 kg/m3) | 7.7-8.03 | 25 | |

| Poisson's Ratio | 0.27-0.30 | 25 | |

| Elastic Modulus (GPa) | 190-210 | 25 | |

| Tensile Strength (Mpa) | 1758 | 25 | oil quenched, fine grained, tempered at 425°C more |

| Yield Strength (Mpa) | 1503 | ||

| Elongation (%) | 8 | ||

| Reduction in Area (%) | 24 | ||

| Hardness (HB) | 600 | 25 | oil quenched, fine grained, tempered at 205°C more |

Machining performance

Download DIN 1.0909 the mechanical properties of the report, the report provides detailed performance analysis and application. Download >>

Principal Design Features

One of the most widely used precipitation hardening grades in the business. While soft and ductile in the solution annealed condition, it is capable of high properties with a single precipitation or aging treatment. Characterized by good corrosion resistance, high harness, toughness and strength.

Machinability

Long, gummy chips characterize this alloys machinability. It can be machined in the annealed condition, however condition H1150M will yield best results. Post machining solution treatment of parts will be required prior to final hardening if machining in this condition.

Heat Treatment

CONDITION A--Soak at 1900 F (1038 C) for 30 minutes and cool below 60 F (16 C) for complete martensite transformation. CONDITION H 950- Treat Condition A material at 900 F(482 C) for 1 hour, air cool.. CONDITION H925, H1025, H1075, H1100, H1150- Soak solution treated material for 4 hours at specified temperature, air cool, CONDITION H1150M- Soak solution treated material at 1400 F (760 C) for 2 hours, air cool, then re-heat to 1150 F (620 C) for 4 hours and air cool.

Welding

Successfully welded by common fusion and resistance methods, this alloy should not be joined by oxyacetylene welding. AWS E/ER630 filler metal is recommended if required.

Forging

Soak for 1 hour at 2150 F (1177 C) prior to forging. Do not work below 1850 F (1010 C). Post-work solution treatment is required prior to final hardening.